In order to extend the service life of commercial vehicle engines and reduce harmful exhaust emissions, engine manufacturers are increasingly using cylinder liners with a fire ring.

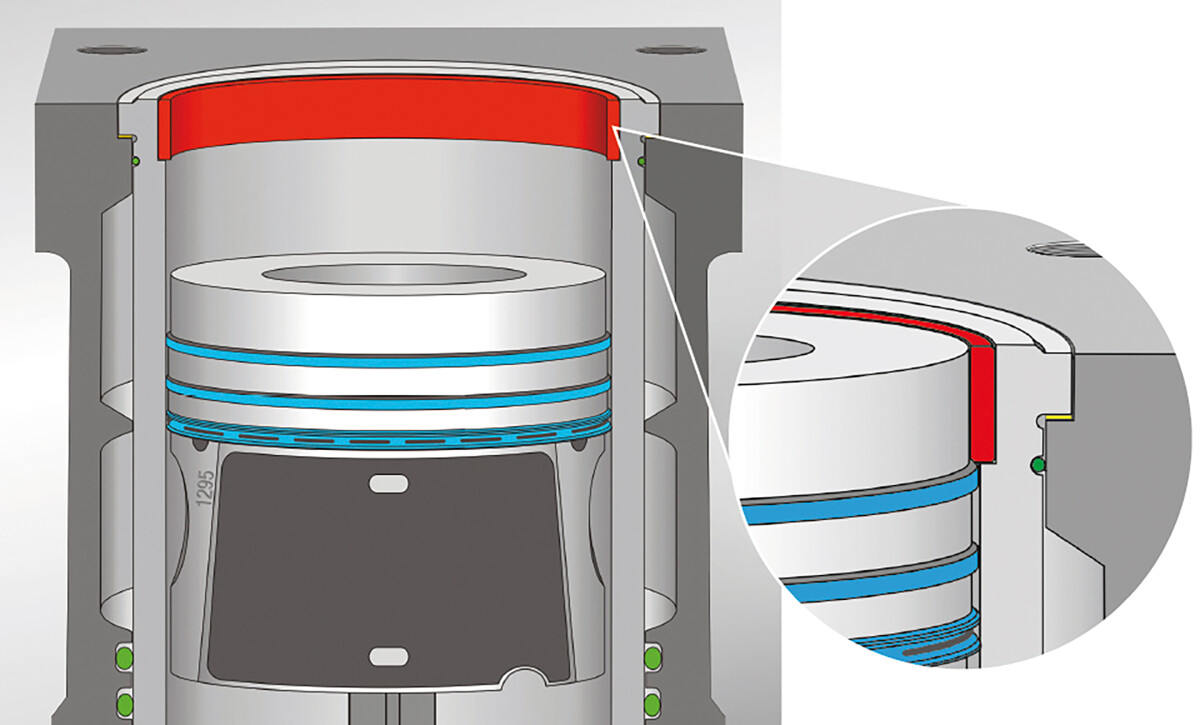

Fire rings are mounted in the upper end of the cylinder liners, in a rectangular recess. During assembly, the fire ring is inserted loosely into the recess. It is then held in position by the cylinder head. The fire ring, also known as the oil carbon scraper ring, prevents the formation of hard oil carbon deposits on the piston's top land. This is achieved by the fire ring's inner diameter being smaller than the cylinder bore. As the piston passes top dead center, the fire ring scrapes unwanted oil carbon deposits from the piston or prevents deposits from forming on the top land (Fig. 1+2). The piston is also designed to accept a fire ring. This is achieved by the smaller inner diameter of the top land compared to other conventional piston designs.

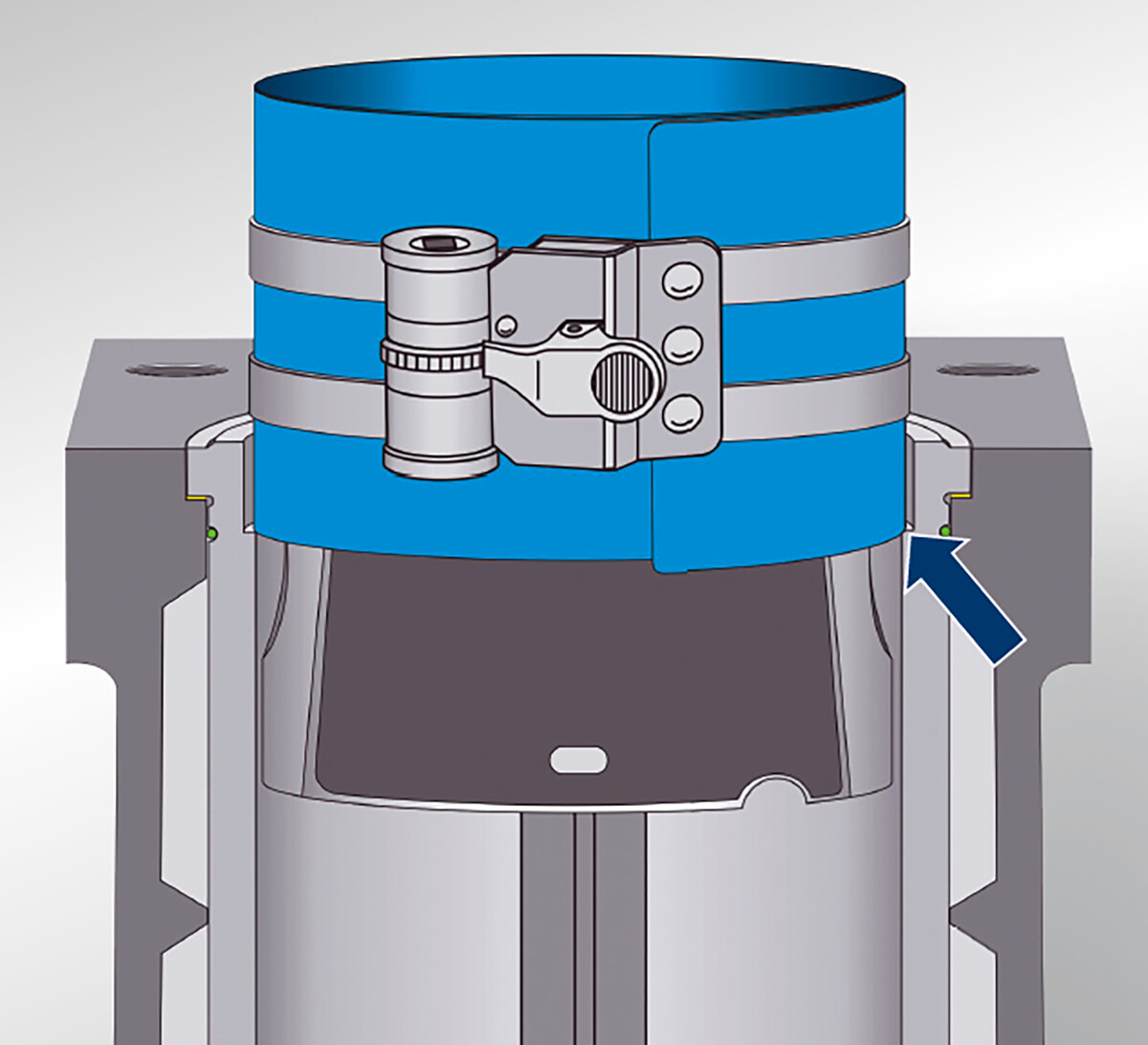

Fig. 2 - Cylinder liner with fire ring

Fig. 2 - Cylinder liner with fire ring

Fig. 1 - Cylinder liner with fire ring

Fig. 1 - Cylinder liner with fire ring

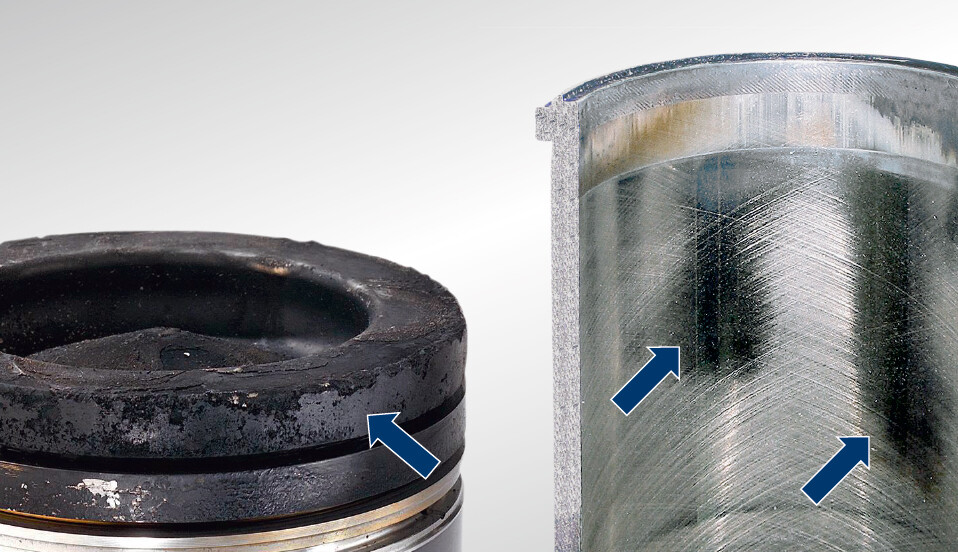

In the case of cylinder liners without a fire ring, a hard layer of oil carbon may form on the piston's fire land under unfavorable engine operating conditions (Fig. 3).

Unfavorable working conditions include, for example:

Fig. 3 - Carbon deposits and abrasive wear

Fig. 3 - Carbon deposits and abrasive wear

Oil carbon deposits on the piston's fire land quickly lead to abrasive wear in cylinder liners without a fire ring. This undesirable, premature wear of the cylinder liners – combined with excessive oil consumption – can be prevented by using cylinder liners with a fire ring.

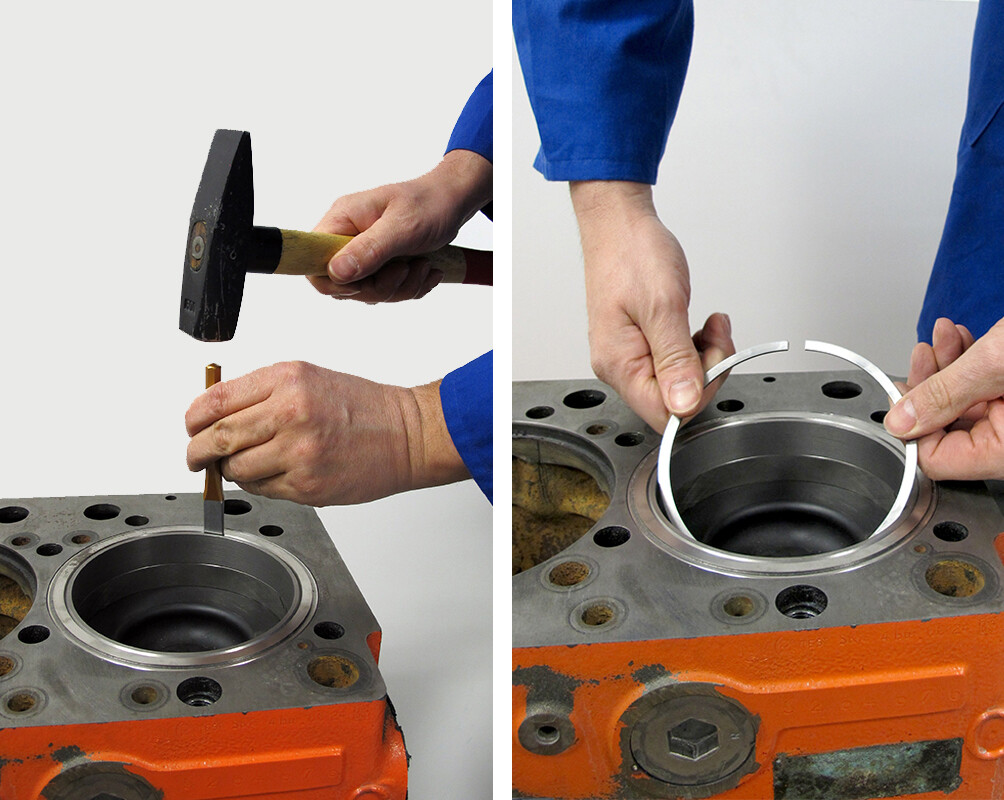

To disassemble the piston , first remove the fire ring from the cylinder liner . With used cylinder liners, this is impossible to do manually without the appropriate tools. Due to the buildup of deposits between the fire ring and the cylinder liner, the fire ring is tightly compressed to its seat. When disassembling damaged cylinder liners, the fire ring can be damaged by driving a chisel between the fire ring and the cylinder liner (Fig. 4).

If the cylinder liner and fire ring are to be reused, first move the piston down slightly by rotating the crankshaft to provide access to the fire ring. Now insert another used piston ring, matching the cylinder diameter, into the cylinder below the fire ring (Fig. 5).

Fig. 4 - Removing damaged cylinder liners

Fig. 4 - Removing damaged cylinder liners

Fig. 5 - Removing the intact cylinder liners

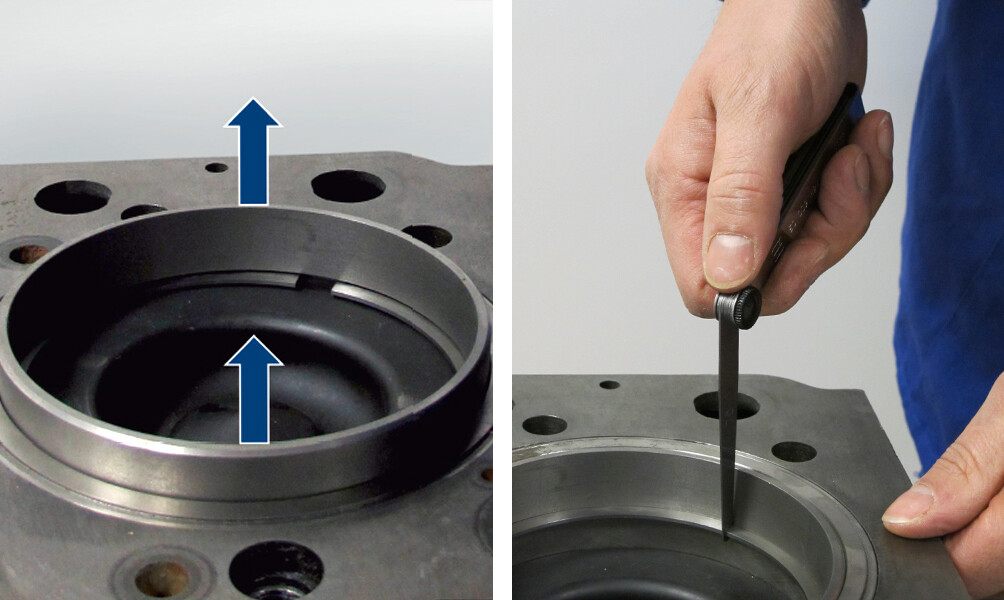

Fig. 6 - pushing out the fire ring

Fig. 6 - pushing out the fire ring

Fig. 7 closing with a gauge

As the crankshaft is rotated, the piston pushes the fire ring out of the cylinder liner (Fig. 6). To prevent the piston ring from being compressed and slipping over the fire ring, the gap created by pushing the fire ring out must be constantly closed with a feeler gauge (Fig. 7).

If only the piston is to be removed, the cylinder liner must be secured in place, i.e., pressed onto its seat. Otherwise, the piston will push the fire ring out of the engine block along with the cylinder liner.

Insert the cylinder liner into the engine block without the fire ring. Then, insert the piston and connecting rod into the cylinder and secure it correctly in the crankshaft. When inserting the piston, ensure that the piston ring retaining band is pushed far enough into the fire ring recess (Fig. 8). This will prevent the piston rings from expanding in the fire ring recess, which would result in damage.

After installing the piston, hand-fit the fire ring into the recess. For used parts, a stiff fire ring can be carefully tapped into the cylinder liner using a hammer and a block of wood. (Fig. 9)

Fig. 8 - Using the tensioning tape

Fig. 8 - Using the tensioning tape

Fig. 9 - Gentle use of force - driving in a used fire ring

Fig. 9 - Gentle use of force - driving in a used fire ring

Kolbenschmidt cylinder liners are always supplied as a complete set , i.e. with a fire ring and sealing rings. Fire rings are not available as separate, individual spare parts.